Products

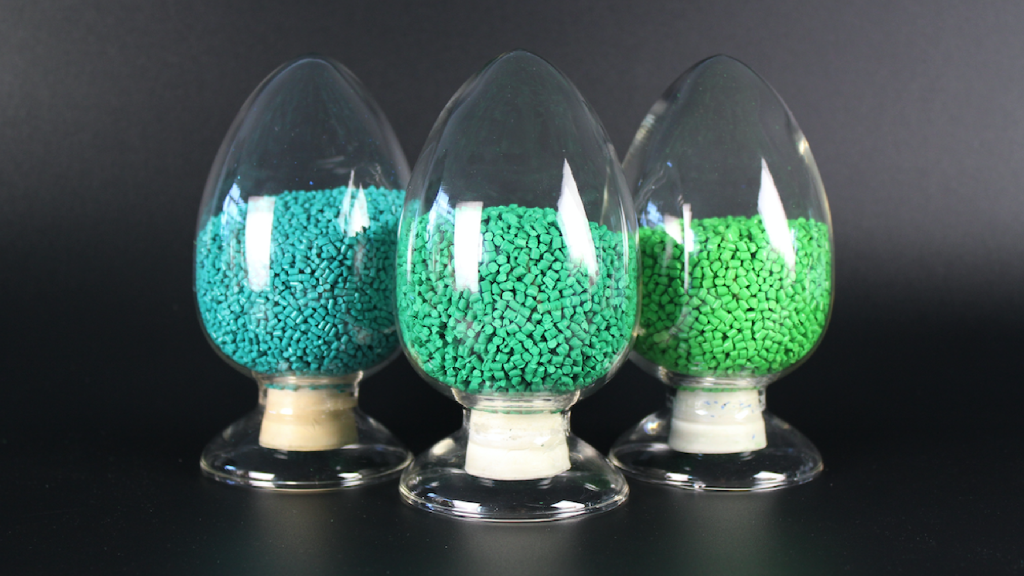

Green Masterbatch

Classification of green masterbatch products: green, olive green, grassland green, dark green, dark green, yellow green, light green, etc. Green masterbatch is mainly used in injection molding products, toy stationery, food packaging, pharmaceutical packaging, plastic pipes, lawn silk, blown film products and other fields. The main characteristics of green masterbatch are bright color, high concentration, high dispersion, strong coloring power, excellent weather resistance and no smell.

Granulation Process

Usage: mix the color masterbatch and plastic raw material particles evenly through the mixer, and dry the color masterbatch if necessary. The color masterbatch can also be fed through the feeding port at the side of the extruder. Through the shearing and mixing of the screw, the color masterbatch can be dispersed to all parts of the plastic to complete the coloring process. This method saves the mixing device and mixing time, which is an economical and practical method. Advantages: easy to use, no dust pollution to the workshop, environmental protection, saving the time of special cleaning equipment after using toner, convenient weighing and accurate measurement. Applicable materials: PE, PP, PA, PVC, pet, PBT, PC, pet, ABS, POM and other plastics.

Gold Masterbatch

Classification of gold masterbatch products: gold, golden yellow, rose gold, Tu Hao gold, light gold, golden brown, etc. The main application of gold masterbatch: packaging industry, electronic and electrical shell, plastic film, etc. The main characteristics of gold masterbatch are: high concentration, strong coloring power, stable color and low precipitation.

Fragrant Masterbatch

Classification of aroma types: light, sweet, fruit, sandalwood, grass, compound, etc. Fragrance classification: jasmine, lily, lilac, grass, leaf, osmanthus, lavender, Magnolia, rose, Luxi, etc. Functional features: it has the function of odor covering, covering up the bad smell in the surrounding environment, increasing the comfort of the environment; increasing the aroma, increasing a special fragrance in the surrounding air, and improving the quality of life. Scope of application: PE, PP, PVC, ABS and other plastics, used in toys, packaging materials, baby carriages, home decoration, garbage bags, etc.

Foaming Masterbatch

Foaming masterbatch is a kind of endothermic closed cell chemical nucleation foaming agent. The use of foaming agent has the advantages of reducing the weight of products, saving materials and reducing costs under the same volume. At the same time, the foaming products can also improve the deformation caused by shrinkage, improve the appearance quality, and have the effect of sound insulation and heat insulation. The use of foaming agent can reduce the holding time of injection molding products and improve the production efficiency. Scope of application: PE, PP, PVC, ABS, PS and other plastics, used in automotive components, home furnishings, boutique, electrical appliances shell and other products.

Flame Retardant Masterbatch

Flame retardant masterbatch is divided into halogen flame retardant, P, N, Br compound flame retardant (close to halogen-free), halogen-free environment-friendly new flame retardant. Flame retardant masterbatch, also known as fireproof masterbatch, is mainly used to prevent fire caused by plastic combustion. In high temperature, flammable environment, schools, hospitals, high-rise buildings, etc., flame retardant plastic products are usually considered, which has higher safety and security. Scope of application: PS, PP, PE, ABS, PBT, PC, PA, PVC and other plastics, used in socket, battery shell, electrical switch, coil framework, rice cooker, electric kettle, heater, wire and cable material, sheath material, high-rise building, hospital curtain, curtain, sofa, carpet and other fiber products.

Film Masterbatch

Product classification: 1, plastic bags, garbage bags, food bags and other packaging bag products. 2. Agricultural film, shed film, plastic film, geomembrane, etc. Product color: black, white, red, gray, blue, gold, green, customized color. Product features: high concentration, high dispersion, strong coloring power, stable color, colorless spots, color lines, no smell and other characteristics.

Film Blowing Process

Usage: Mix the masterbatch particles with the plastic raw material particles uniformly through the mixer, feed them, and produce blown film products. If necessary, dry the masterbatch particles. The thinner the thickness of the film product, the higher the proportion of masterbatch. Advantages: easy to use, will not cause dust pollution to the workshop, environmental protection, and saves the time for special cleaning of the equipment after using toner. Applicable materials: LDPE, LLDPE, HDPE, ULDPE, EVA, EAA, PP, PA and other plastics.

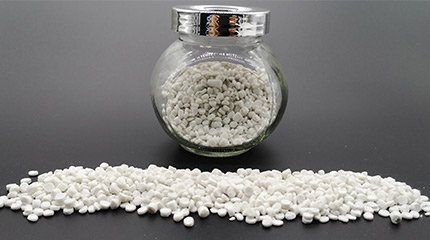

Filling Masterbatch

Product category: talcum powder filled masterbatch, sodium sulfate filled masterbatch, barium sulfate filled masterbatch, calcium carbonate filled masterbatch. The filler masterbatch is composed of carrier, filler and additives, which can improve the dimensional stability and hardness index of the product, and reduce the addition of raw resin materials and cost. Scope of application: PP, PE, PS, ABS and other plastics, used in plastic film, packaging bags, garbage bags, injection molded products, extruded products, sheet, plate and other fields.