Products

PBT Masterbatch

Color classification: gray, white, green, red, blue, black, etc., custom colors. Scope of application: keyboard, mudguard, shell of household appliances, connector, industrial product parts, cooling fan, socket, base, power adapter, electric iron handle, hair dryer, hot melt spray gun, ski connector and other products. Product advantages: high dispersion, high concentration, strong coloring power, low precipitation, excellent color quality, stable color and weather resistance.

Packing Masterbatch

Product classification: 1, plastic bags, garbage bags, food bags and other packaging bag products. 2. Agricultural film, shed film, plastic film, geomembrane, etc. Product color: black, white, red, gray, blue, gold, green, customized color. Product features: high concentration, high dispersion, strong coloring power, stable color, colorless spots, color lines, no smell and other characteristics.

Orange Masterbatch

Classification of orange masterbatch products: orange, orange red, orange yellow, bright orange, etc. The main application of orange masterbatch: wires and cables, packaging, PVC pipes, PE pipes, PP pipes, injection products, packaging bags, plastic films, etc. Features of orange masterbatch: stable color, no migration, weather resistance, strong coloring power and high dispersion.

Open mouth smooth

The use of open smooth masterbatch can form a layer of molecular film on the surface of the product and form a micro concave convex structure on the surface of the plastic, which can reduce the problem of product adhesion. It has good smooth performance, low friction and opening property, and can also avoid the phenomenon that the product is easy to adhere to the screw and lead to the feed slip. In the whole process, there is a lubrication effect. Scope of application: PP, PE, LDPE, PVC, HDPE, EVA, pet and other plastics, used in film, packaging bag, flat bag, calendering film, heat shrinkable film.

Injection Molding Process

How to use: Mix the masterbatch and plastic particles uniformly through the mixer, injection molding according to the normal process, and drying the masterbatch if necessary. Advantages: no need to mix with toner, pollute the workshop environment, easy to use, no special cleaning of the equipment is required after use. Applicable materials: PE, PP, PVC, ABS, PS, PA, PC, PBT, POM, PET, PMMA, TPV and other plastics.

Injection Masterbatch

Product classification: PA, PC, ABS, PBT, POM, PMMA, pet, etc. Product color: black, white, blue, green, silver, gray, custom color. Product features: the company uses high-quality special resin carrier, selected pigments, additives, after multiple attempts to mix, the optimized formula. The product has the characteristics of high dispersion, high concentration, good compatibility with resin, strong coloring power, non-toxic, tasteless, stable quality, bright color, excellent migration resistance, no color lines and spots, and excellent heat resistance.

Hardening Masterbatch

The hardener masterbatch is composed of carrier, high-quality minerals and functional additives 1. Improve the rigidity and hardness of plastic products and the dimensional stability of products; 2. Improve the heat resistance of plastics. 3. Reduce plastic deformation due to shrinkage. 4. It has antioxidant and anti-aging effects, and prolongs the service life of products. Scope of application: PE, PP, PVC, PS and other plastics, mainly used in plastic pipes, automotive interior, household appliances, etc.

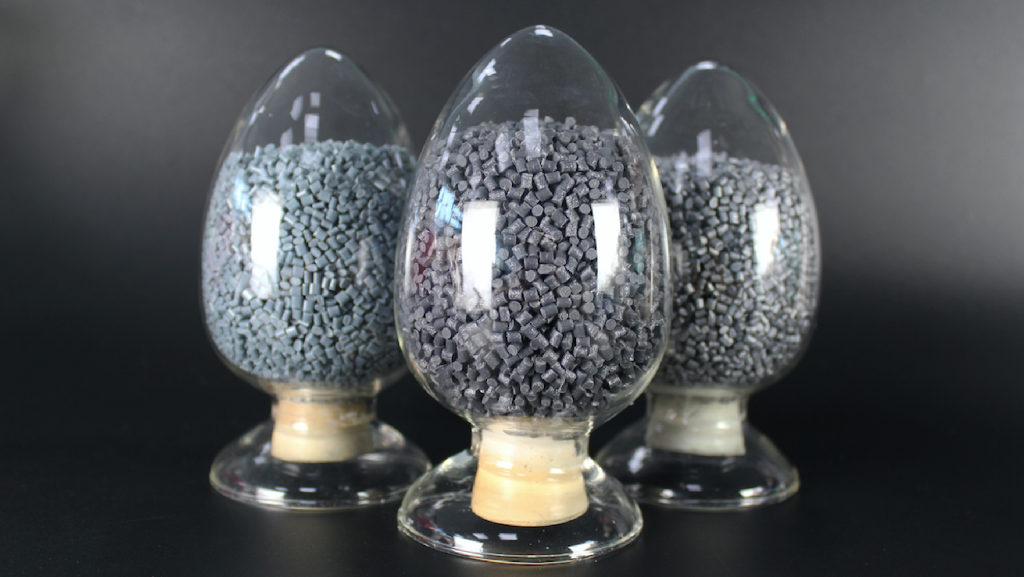

Grey Masterbatch

Classification of grey masterbatch products: light grey, dark grey, blue grey, silver grey, lead grey, etc. The main application of gray masterbatch: Express bag, sheet material, PPR pipe, turnover box, injection products, household appliances, electric tools, oil pot, etc. Characteristics of gray masterbatch: high concentration, good dispersion, no migration, color stability, economy and so on.