CMB Expert

High Quality Dispersible Masterbatch Supplier In China

Focus on Masterbatch

Factory area

Product Capacity

Product Center

Yellow Masterbatch

Yellow masterbatch product classification: yellow, light yellow, medium yellow, yellow, orange, orange. Application of yellow masterbatch products: pipes, plastic containers, plastic films, injection molded products, toys, wires and cables, drawing woven bags, etc. Characteristics of yellow masterbatch: it has bright color, high concentration, strong coloring power, no migration and temperature resistance.

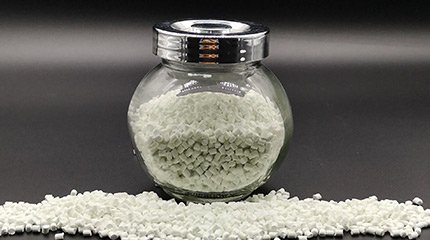

Whitening and brightening

Product features: the main function of this product is to improve the whiteness and brightness of recycled plastics, eliminate yellowing and blackening, improve the appearance color quality, and play a new effect. In the production process of some new plastics with a small amount of recycled materials, the color becomes black because of the influence of recycled materials. The use of whitening and brightening masterbatch can obviously improve the color quality, and has little effect on the physical and mechanical properties of plastic pigments. Scope of application: PS, PP, PE, ABS, PC, recycled materials, etc.

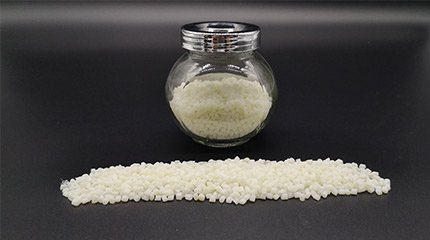

White Masterbatch

White Masterbatch product classification: milky white, pure white, porcelain white, bright white, etc. Functional classification of White Masterbatch: General White Masterbatch and special White Masterbatch. The main application of White Masterbatch: blowing film, injection molding, pipe, drawing, tape casting, plate, packaging, etc. Characteristics of White Masterbatch: high whiteness, high covering, high dispersion and low precipitation.

Weathering Masterbatch

The composite formulation of light stabilizer and heat stabilizer can reduce the degree of photodegradation and thermal oxidation reaction of plastics caused by light and heat, and keep the mechanical properties of outdoor plastic products stable for a long time: tensile, bending, impact, elongation at break and other properties, which can prolong the service life of plastic products. The weather resistant masterbatch is suitable for the application environment with high degree of severity, such as wind blowing, sunlight, rain and so on. Scope of application: PE, PP, PA, ABS, PBT, ABS, PC, POM and other plastics, used in automobile interior, sports facilities, seats, outdoor plastic products, etc.

UV resistant Masterbatch

UV resistant masterbatch contains anti UV additives, which can reduce the rate of photooxidation of outdoor injection molded products, reduce the decline rate of plastic tensile strength and elongation, prolong the outdoor yellowing time and service life of polyolefin products. Scope of application: PE, PP, PVC, ABS, PS, PC, PA, POM, pet, PMMA, outdoor products, tents, sunshade nets, curtain plastic products.

TPE / TPR

Color classification: black, white, orange, green, yellow, blue, etc., custom colors. Scope of application: soft rubber toys, hose, telescopic water pipe, glasses foot cover, wire and cable, insole, heel, tension tube, yoga mat, intelligent bracelet, handle cover, anti slip pad, elastic plastic parts, automobile sealing strip, car foot pad, automobile bellows, electronic wire rod, hose, etc. Product advantages: high concentration, strong coloring power, high dispersion, low precipitation, weather resistance, color stability, heat stability and other characteristics.